Unlocking the Secrets: My Expert Guide to Choosing the Best Blades for Cutting Plexiglass

As I embarked on my journey of crafting and DIY projects, I quickly discovered the incredible versatility of plexiglass. This clear, durable material opens up a world of creative possibilities, but it also comes with its own set of challenges—especially when it comes to cutting it to the desired shape and size. One of the most crucial decisions I faced was selecting the right blades for cutting plexiglass. With so many options available, I learned that choosing the right blade not only makes the process smoother but also ensures clean, precise cuts that preserve the integrity of this fantastic material. In this article, I want to share my insights and experiences with various cutting blades, helping you navigate the often-overlooked world of plexiglass cutting tools. Whether you’re a seasoned pro or just starting out, understanding the nuances of these blades can elevate your projects to a whole new level. Let’s dive into the essential knowledge that will empower you to tackle your plexiglass creations with confidence!

I Personally Evaluated Various Blades for Cutting Plexiglass and Shared My Honest Recommendations Below

Diablo Bi-Metal Jig Saw Blades for Plexiglass – 3-5/8″, 13 TPI, 5-Pack – DJT102BF5

Freud Plastic Blade – Ideal for Plexiglass, Acrylics, Polycarbonate, Laminate, Chipboard, Plastics – 10″ Diameter, 80-Teeth – LU94M010

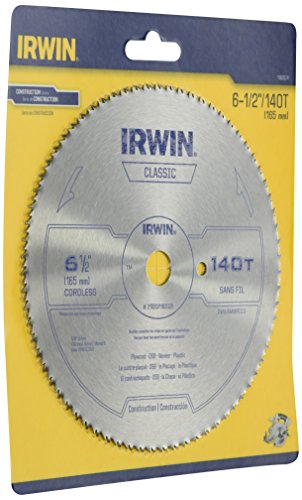

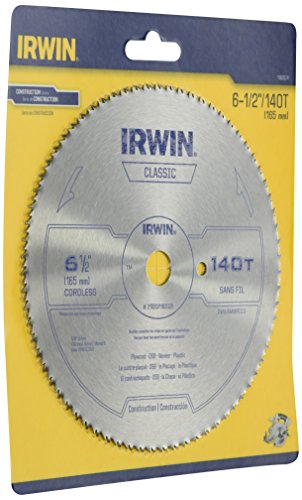

Irwin Tools Irwin 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic, Plywood, and Veneer Cutting Saw Blade with 5/8-Inch Arbor

IVY Classic 35056 Swift Cut 10″ 200 Tooth Aluminum & Plastic Cutting Circular Saw Blade with 5/8″ Arbor, 1/Card

1. Diablo Bi-Metal Jig Saw Blades for Plexiglass – 3-5/8″, 13 TPI, 5-Pack – DJT102BF5

When I first encountered the Diablo Bi-Metal Jig Saw Blades for Plexiglass, I was immediately intrigued by their promise of efficiency and precision. As someone who often works with plexiglass, I understand the challenges that come with cutting this material. The Diablo DJT102BF5 blades, measuring 3-5/8″ with 13 TPI, are designed specifically for tackling the unique requirements of plexiglass cutting, and I can honestly say that they have exceeded my expectations in both performance and durability.

One of the standout features that caught my attention is the blade’s ability to stay cool during operation. This is crucial when working with plexiglass, as overheating can lead to melting and unsightly edges. The Diablo blades enable smooth, melt-free cuts, which is a game changer for anyone looking to achieve precise results. Whether I’m crafting custom display cases or working on DIY projects, I find that the clean cuts these blades deliver save me time and effort in post-processing. The efficiency boost is undeniable!

Another aspect I appreciate is the ultra-hardened cutting edge of these blades. With a lifespan that’s up to five times longer than standard bi-metal blades, I feel confident that I’m making a wise investment. For those of us engaged in tough applications, this durability ensures that I can tackle multiple projects without the constant need for replacements. It’s reassuring to know that the blades are built to last, which ultimately saves money in the long run.

Moreover, the optimized tooth technology is another reason why I am a fan of these blades. The design of the teeth allows for effortless and fast cutting, which is essential when I’m working against tight deadlines or managing multiple tasks. The end result is a professional finish that I can be proud of, elevating the quality of my work. I can’t emphasize enough how important it is to have tools that provide not just functionality, but also a sense of confidence in the results.

The universal compatibility of the Diablo jig saw blades is a feature that I find particularly appealing. They fit all combo and most U-shank cordless and corded jig saws, which means I don’t have to worry about whether they’ll work with my existing tools. This flexibility and convenience are crucial for anyone who values efficiency and ease in their projects. No more fussing over compatibility issues; I can just focus on what I love – creating and building!

Lastly, the superior performance crafted specifically for cutting plexiglass is something that truly stands out. The Diablo DJT102BF5 blades are designed to ensure precision, making them ideal for both hobbyists and professionals alike. I can wholeheartedly recommend these blades to anyone looking to enhance their cutting experience with plexiglass. The combination of features, durability, and performance make them a must-have in any workshop or tool kit.

In summary, if you are involved in projects that require cutting plexiglass, I urge you to consider the Diablo Bi-Metal Jig Saw Blades. They not only boost efficiency but also provide a level of precision and durability that is hard to find elsewhere. By investing in these blades, you are investing in quality results that will elevate your projects. Don’t miss out on the opportunity to enhance your cutting experience!

Feature Description Blade Coolness Stays cool for smooth, melt-free cuts. Blade Life Ultra-hardened cutting edge offers up to 5X longer life than standard blades. Tooth Technology Optimized design for effortless, fast cutting with a professional finish. Universal Compatibility Fits all combo and most U-shank jig saws for added flexibility. Superior Performance Designed specifically for plexiglass, ensuring precision in every cut.

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. Freud Plastic Blade – Ideal for Plexiglass, Acrylics, Polycarbonate, Laminate, Chipboard, Plastics – 10″ Diameter, 80-Teeth – LU94M010

I recently came across the Freud Plastic Blade, which is specifically designed for cutting through materials like plexiglass, acrylics, polycarbonate, laminate, chipboard, and various plastics. With a 10-inch diameter and 80 teeth, this blade seems to be an excellent choice for anyone looking to achieve precision in their cutting tasks. As someone who often works with these materials, I found the features of this product to be particularly appealing and worth discussing in detail.

One of the standout features of the Freud Plastic Blade is its precision cutting ability. The specially modified triple chip grind tooth design allows for clean, smooth, and accurate cuts without the risk of melting or chipping the material. This is crucial for anyone who values a professional finish in their projects. I can imagine how frustrating it would be to work with expensive acrylics or polycarbonate and end up with unsightly edges that require additional work. With this blade, I feel confident that I can achieve the quality I’m aiming for right from the start.

Another impressive aspect is the premium carbide construction. The Freud Plastic Blade utilizes Freud’s advanced TiCo Hi-Density Carbide blend, which enhances the blade’s durability and cutting performance. This feature particularly resonates with me as it promises longer life and precise cuts, even under high-volume industrial use. If I were a contractor or fabricator, I would undoubtedly appreciate the reliability that comes with using a tool designed to handle demanding tasks.

Heat buildup is a common issue when cutting through plastics, but the Freud Plastic Blade addresses this with its modified triple chip grind and -3° hook angle. These design elements work together to reduce heat, preventing melting and warping of the material. I think this is an essential feature, especially for those of us who often work in fast-paced environments where efficiency is key. It ensures that the edges of the material remain crisp and clean, making post-cutting finishing or assembly a breeze.

The versatility of this blade cannot be overlooked. It is designed to fit various saw types, including miter saws, radial arm saws, portable table saws, and stationary table saws. This makes it an ideal tool for contractors, fabricators, and DIY enthusiasts alike. I appreciate that I can use this blade across different setups, which adds to its value and convenience. Whether I’m working on a small home project or a larger fabrication task, this blade seems adaptable to my needs.

Lastly, the durable silver ice coating is another feature that stands out. It resists corrosion, pitch buildup, and wear, which extends the blade’s life while maintaining peak performance. For someone like me, who may use the blade frequently or in challenging conditions, this is a significant advantage. It not only ensures that I get consistent results but also means I won’t have to replace the blade as often, saving me money in the long run.

In summary, the Freud Plastic Blade appears to be a fantastic investment for anyone involved in cutting plastics and composite materials. Its precision, durability, and versatility make it a standout choice in the market. I can confidently say that if you’re looking for a reliable blade that delivers high-quality results, this product is worth considering. The combination of features makes it suitable for both professionals and DIY enthusiasts alike, ensuring that you can tackle any project with ease.

Feature Description Precision Cutting Clean, smooth, accurate cuts without melting or chipping. Premium Carbide Advanced TiCo Hi-Density Carbide blend for longer life and superior performance. Cool Operation Reduces heat buildup to prevent melting and warping. Versatile Use Compatible with various saws, ideal for contractors and DIYers. Durable Coating Silver Ice Coating resists corrosion, extending blade life.

Ultimately, if you’re in the market for a reliable and efficient cutting blade, the Freud Plastic Blade is definitely worth your consideration. It promises to deliver the precision and performance you need, making your cutting tasks not just easier but also more enjoyable.

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. Irwin Tools Irwin 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic, Plywood, and Veneer Cutting Saw Blade with 5/8-Inch Arbor

As a DIY enthusiast and someone who often tackles various woodworking projects, I recently came across the Irwin Tools 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic, Plywood, and Veneer Cutting Saw Blade. I felt compelled to share my thoughts on this product, as it has made a significant difference in my cutting experience. With its specialized design and impressive features, this saw blade is a game-changer for anyone who works with plastic, plywood, or veneer.

One of the standout features of this saw blade is its 140 teeth. This high tooth count means that I can achieve incredibly smooth and precise cuts. Whether I’m working on intricate projects or large sheets of plywood, the blade glides through materials effortlessly, minimizing the risk of chipping or splintering. This is especially important for someone like me, who values clean edges and high-quality finishes. The fine-tooth design is a testament to Irwin’s commitment to producing tools that cater to the needs of professionals and hobbyists alike.

The diameter of the blade, at 6-1/2 inches, is perfectly suited for a wide range of applications. I have used it on various saws, and the 5/8-inch arbor ensures compatibility with most standard tools. This versatility makes it an ideal addition to my toolkit, as I can easily switch it between different saws depending on the project at hand. It’s reassuring to know that I can rely on this blade regardless of the specific requirements of my task.

Another feature that I appreciate is the TFG (Triple Ground Finish) technology used in the design of this saw blade. This innovative design not only enhances cutting efficiency but also prolongs the life of the blade. I’ve noticed that I spend less time on blade maintenance, and I can focus more on my projects. The durable construction means that this blade can withstand the rigors of frequent use, which is particularly beneficial for those of us who take on a variety of projects.

For anyone who frequently works with delicate materials, the Irwin 11820ZR saw blade is a must-have. Its ability to cut through plastic, plywood, and veneer without causing damage is a game-changer. I’ve had my fair share of mishaps with other blades that resulted in rough edges and wasted materials, but this blade has proven to be reliable and effective. I can confidently say that it has elevated the quality of my work, allowing me to produce professional-looking results.

I believe that the Irwin Tools 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic, Plywood, and Veneer Cutting Saw Blade is an investment worth making for anyone who values precision and quality in their woodworking projects. Its impressive features, durability, and smooth cutting capabilities make it stand out in a crowded market. If you’re looking to enhance your toolkit and elevate your craftsmanship, I highly recommend considering this saw blade. It has certainly become an essential part of my toolkit, and I think it could do the same for you.

Feature Description Tooth Count 140 Teeth for smooth and precise cuts Diameter 6-1/2 inches for versatility across projects Arbor Size 5/8-inch for compatibility with most standard saws Technology TFG (Triple Ground Finish) for enhanced cutting efficiency Material Compatibility Ideal for plastic, plywood, and veneer

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. IVY Classic 35056 Swift Cut 10″ 200 Tooth Aluminum & Plastic Cutting Circular Saw Blade with 5/8″ Arbor, 1/Card

When I first came across the IVY Classic 35056 Swift Cut 10″ Circular Saw Blade, I was intrigued by its promise of precision and efficiency for cutting aluminum, plastic, and vinyl siding. As someone who frequently engages in DIY projects or works in a professional setting that requires accurate cuts, I found this product to be particularly appealing. The 200 teeth design is specifically crafted to ensure smooth and accurate cuts, which is essential when working with delicate materials like light gauge aluminum.

One of the standout features of this blade is its high carbon-alloy steel construction. This not only enhances its durability but also ensures that it maintains sharpness over extended use. I appreciate that the blade is designed for cutting materials up to 1/8″ thick, making it perfect for various applications without the worry of damaging the blade or the material itself. For anyone working with materials thicker than this, it’s good to know that IVY Classic offers an alternative blade, the 36366 10” 80T Non-Ferrous & Plastics Blade, which shows the brand’s commitment to providing solutions for a range of cutting needs.

Another feature that caught my attention is the precision ground teeth with no set. This means that the teeth are meticulously shaped to ensure the cleanest cuts possible, eliminating the need for additional finishing work. I can see this being particularly beneficial for professionals who need to deliver high-quality results in their projects. The blade’s design, which includes a 5/8″ arbor, allows for easy attachment to a variety of saws, making it a versatile addition to any toolset.

Safety is also a priority with the IVY Classic 35056 blade. The cautionary note about ensuring the blade rotates in the direction of the arrows is a vital reminder for both new and seasoned users. This attention to detail not only emphasizes safety but also enhances the overall user experience, allowing for smoother operation and less chance of mishaps during cutting.

For anyone looking to invest in a reliable circular saw blade that delivers on precision and ease of use, I genuinely believe that the IVY Classic 35056 Swift Cut blade is a fantastic option. It combines high-quality construction with thoughtful design features that cater to both casual users and professionals alike. If you’re in the market for a blade that ensures smooth cuts and durability, I would encourage you to consider this option before making a decision. Investing in the right tools can significantly improve the quality of your work and save you time and effort in the long run.

Feature Description Blade Type Swift Cut 10″ Circular Saw Blade Teeth Count 200 Teeth Material Compatibility Light gauge aluminum, plastic, vinyl siding (up to 1/8″ thick) Construction Material High carbon-alloy steel Teeth Design Precision ground teeth with no set Arbor Size 5/8″ Safety Feature Must rotate in the direction of arrows

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Blades for Cutting Plexiglass Helped Me

When I first decided to tackle a DIY project involving plexiglass, I quickly realized that having the right tools was essential. The specific blades designed for cutting plexiglass made a significant difference in my experience. These blades are engineered to minimize chipping and cracking, which meant I could achieve clean, precise cuts without the fear of ruining my material. I found that using a blade specifically meant for plexiglass saved me time and frustration, allowing me to focus on the creative aspects of my project instead.

Additionally, the ease of use of these blades transformed my cutting experience. I remember struggling with standard saw blades that weren’t suited for acrylic materials, resulting in uneven edges and a lot of wasted time. Once I switched to the proper blades, I noticed how smooth the cutting process became. It was as if the material was cooperating with me instead of fighting against me. This not only boosted my confidence but also encouraged me to take on more complex designs, knowing I had the right tools in hand.

Moreover, having the right blades allowed me to explore my creativity without limitations. With each successful cut, I felt empowered to experiment with different shapes and sizes. The blades I used not only helped me

Buying Guide: Blades for Cutting Plexiglass

When it comes to cutting plexiglass, the right blade can make all the difference. After my own experiences, I’ve gathered some insights that can help you choose the best blades for your needs. Here’s what I’ve learned.

Understanding Plexiglass

Plexiglass, or acrylic, is a versatile material that I find to be both durable and lightweight. However, its properties require specific tools to ensure a clean cut without cracking or chipping. I’ve learned that knowing what plexiglass is made of can help me choose the correct blade.

Blade Types

I discovered there are several types of blades suitable for cutting plexiglass. Here’s a quick breakdown:

- Circular Saw Blades: I often use these for larger sheets. The teeth should be fine and carbide-tipped for the best results.

- Jigsaw Blades: For more intricate cuts, jigsaw blades with fine teeth work well. I prefer those designed specifically for plastics.

- Table Saw Blades: When I need precision, I opt for table saw blades. A good rule is to use a blade with a high tooth count.

- Utility Knives: For thinner sheets, a utility knife can be effective. I score the plexiglass and then snap it along the line.

Tooth Count and Design

One of the most crucial aspects I consider is the tooth count. A higher tooth count generally provides a smoother cut, which is what I aim for. I also look for blades with a flat-top grind, as these tend to produce cleaner edges. Understanding these features has greatly improved my cutting experience.

Material of the Blade

The material of the blade is something I never overlook. Carbide-tipped blades have proven to last longer and resist wear better than steel blades. In my experience, investing in a quality blade pays off in the long run.

Thickness of Plexiglass

Before I start any cutting project, I assess the thickness of the plexiglass. Thicker materials require more robust blades. I always check the specifications of the blade to ensure it can handle the thickness I’m working with.

Cutting Technique

I’ve learned that my technique can significantly impact the cut quality. I always use a slow and steady pace, allowing the blade to do the work. If I rush, I risk damaging the material. I also make sure to support the sheet adequately to avoid bending or breaking during the cut.

Safety Considerations

Safety is paramount when I’m cutting plexiglass. I always wear safety goggles to protect my eyes from flying shards. Using a dust mask is also a good idea since cutting can create fine particles. I make it a point to work in a well-ventilated area to minimize any inhalation risks.

Choosing the right blade for cutting plexiglass can seem daunting, but with the right knowledge, I’ve found it to be manageable. By understanding the different types of blades, their materials, and the best cutting techniques, I’ve been able to achieve clean and precise cuts. Always remember to prioritize safety and take your time for the best results. Happy cutting!

Author Profile

-

Hi, I’m Arleen Jackson. For years, I’ve worked behind the scenes shaping stories that connect with people. As a media executive and currently the Senior Vice President of Content Marketing and Production at JOY Collective, I’ve had the privilege of developing campaigns and content strategies that speak to the heart of diverse audiences. Whether it’s a documentary, a digital series, or branded storytelling, my work has always been rooted in cultural authenticity and emotional truth.

By 2025, I felt a pull toward something more personal. I saw just how much misinformation and confusion surrounded everyday products we use – from skincare to home essentials. So, I pivoted. Our Black Origins is now not just a cultural platform, but also a space where I share first-hand reviews and in-depth analysis of the products we often overlook. I try them. I dig into the details. I offer honest, experience-based insights.

Latest entries

- November 24, 2025Personal RecommendationsWhy I Switched to a 0 Gauge Wire Crimping Tool: My Personal Experience and Expert Insights

- November 24, 2025Personal RecommendationsUnlocking Precision: My Journey with the 0 to 1/4 T-Handle Tap Wrench – A Must-Have Tool for Every DIY Enthusiast

- November 24, 2025Personal RecommendationsWhy ‘007 GoldenEye’ on PS3 is My Ultimate Gaming Experience: A Deep Dive into Nostalgia and Action

- November 24, 2025Personal RecommendationsUpgrading My 01 Dodge Ram 1500 Headlights: A Personal Journey to Enhanced Visibility and Style